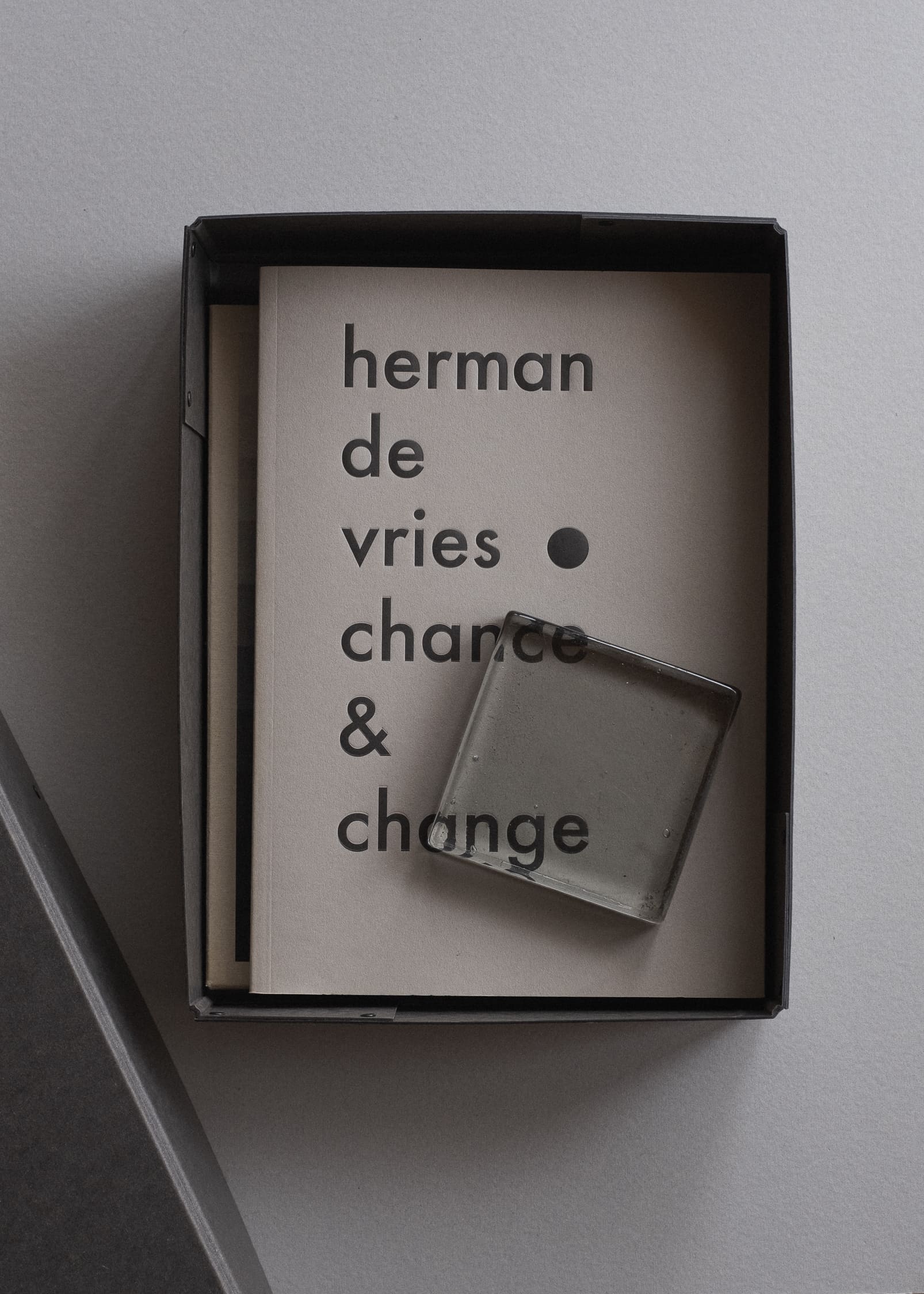

Collecting and organizing, forgetting and re-discovering. Lift up the lid and look down what you put in the box from above. This box may bring you new discoveries that you’ve never come across. Made with hard fiberboard. Firmly fixed with metal rivets. Light weight. High in strength and durability. Manufactured by Takeuchi Shiki Seisakusho and FROME.

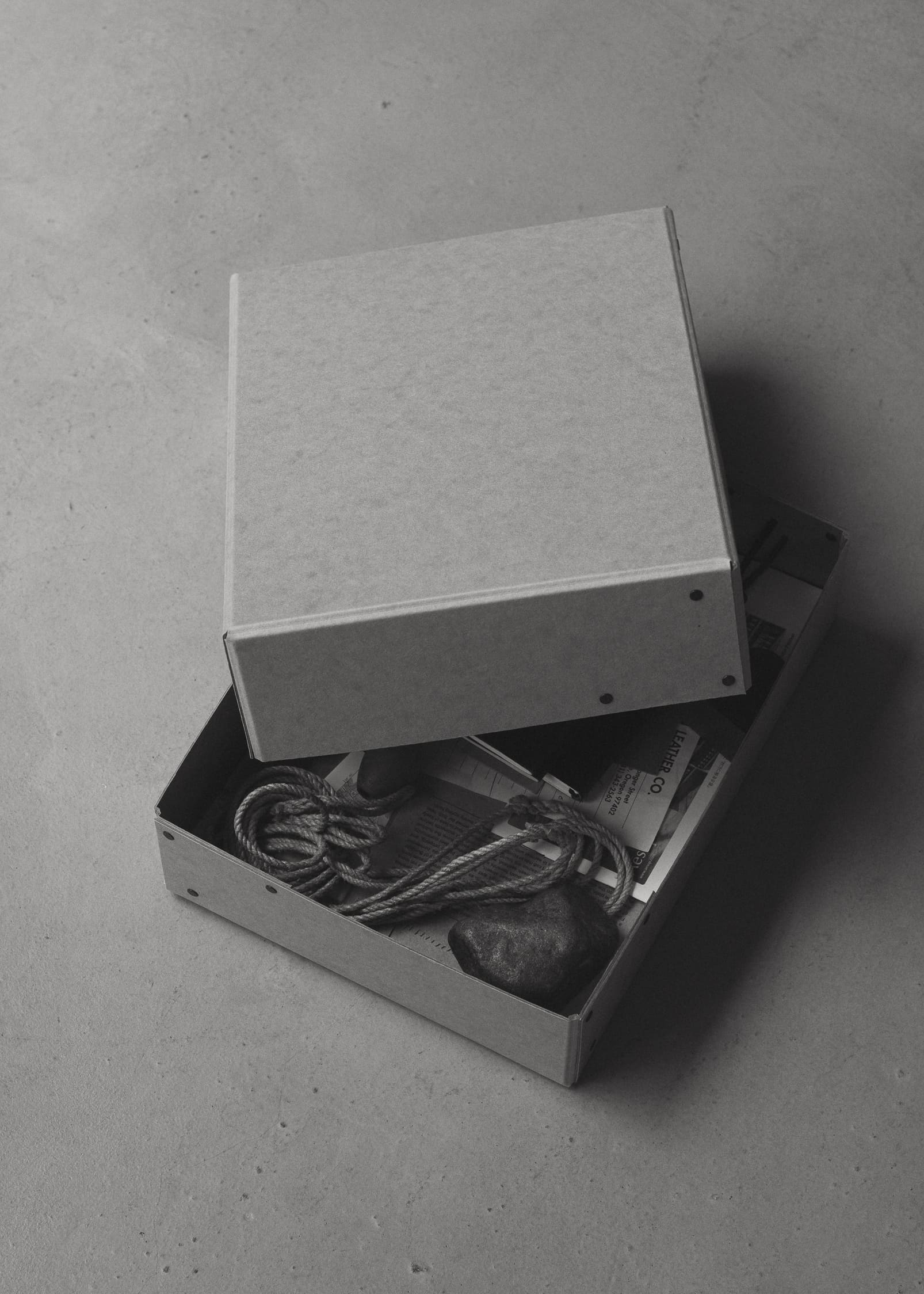

To put things in a box is to maintain a good psychological distance from them. When you put things in a box and look into the box again when their existence has faded from your consciousness, your view of things changes and you discover something you hadn't noticed before. Storage and organisation, forgetting and rediscovering are the themes of the box.

The size of the box is A4, which is large enough to hold A4 paper, a common type of document, and still have room in the top, bottom, left and right sides. The 'format' of A4 is suitable for organising, thinking, discovering and conceiving. Deep enough to hold documents and accompanying materials together. The size is just right for storing miscellaneous items that you want to keep together, or for organising project-based materials.

Box material. Although I admire heavy materials such as wood and leather, I want something easier to use without any fuss. Sturdy paperboard boxes, like the storage boxes that line the shelves of hardware and button shops. If the surface is made of the core material without any pasting, the pasting will not peel off, even if it gets fluffed up after use. They are durable and have a good texture that can be used for a long time.

I originally used boxes made of rigid fibreboard at home. It is strong, can adapt to slight changes in shape and is lightweight. It also has a good texture made from pulp and used paper, and we wondered if we could make boxes from this material. Rigid fibreboard is often coated on the surface to enhance its durability and design, but we dared not to do so and decided to utilise the colour and texture of the base material itself. The slight irregularities on the surface and the roughness of the fibres. Although not as resistant to water or stains as coated materials, the change in texture is easily felt and the material can be loved for a long time.

The rivets that hold the board in place are gilded in matt black. Compared to ordinary gilding colours, it is characterised by a deep black colour, and the slight individual differences that it produces are deeply tasty. The box is firmly fixed with three rivets on each side and 24 rivets in total on the body and lid, so that the box as a whole does not flex easily.

In making the box, we wanted to emphasise its box-like appearance as an industrial product. Mass-produced products with traces of human presence, which were commonplace until a few decades ago. They decided to consult Takeuchi Shiki Seisakusho, a paper box professional who knew how manufacturing was done back then and continues to meet the demands of various customers today. There was no precedent for processing board materials, and some adjustments were difficult, but they were able to devise a solution based on their long-accumulated experience and the tactfulness that comes from it. The factory is staffed by skilled, mid-career and young workers, who are constantly accumulating technology and incorporating new ideas. With the help of such a technical group, we are very proud that we were able to give actual shape to the ideas we had imagined.

In this project, Takeuchi Shiki Seisakusho is responsible for the die-cutting and streak-stamping process, while FROME is responsible for the assembly process.

FROME's advocacy of 'handcraft' is broader than generally thought, and includes industrial products that show traces of the human presence that was commonplace about half a century ago. In the period when the Bauhaus opened its doors, industrial products were made on the basis of mass production, but traces of hands could be felt, which could be seen as modern handcrafts. Traces of human presence, skill and work. I hope that FROME's involvement will become someone else's experience and be utilised, standing on what many people have acquired through their various experiences so far.

Outside dimensions: 330×250×85mm

Inside dimensions: 305×225×80mm

| Weight | 500 g |

|---|---|

| Dimensions | 330 × 250 × 85 mm |

| リベットカラー | Black, Nickel Silver |

| Attention | ◯本製品には木材繊維(古紙・フレッシュパルプ等)を主原料とした特殊硬質繊維ボ-ド「パスコ 」を使用しています。 - PASCO is a special hard fibre board made mainly from wood fibres (recycled paper, fresh pulp, etc.). |

Related products

-

Archival storage box “Rivet Box” - Charcoal Gray

¥ 5,940 Including sales tax -

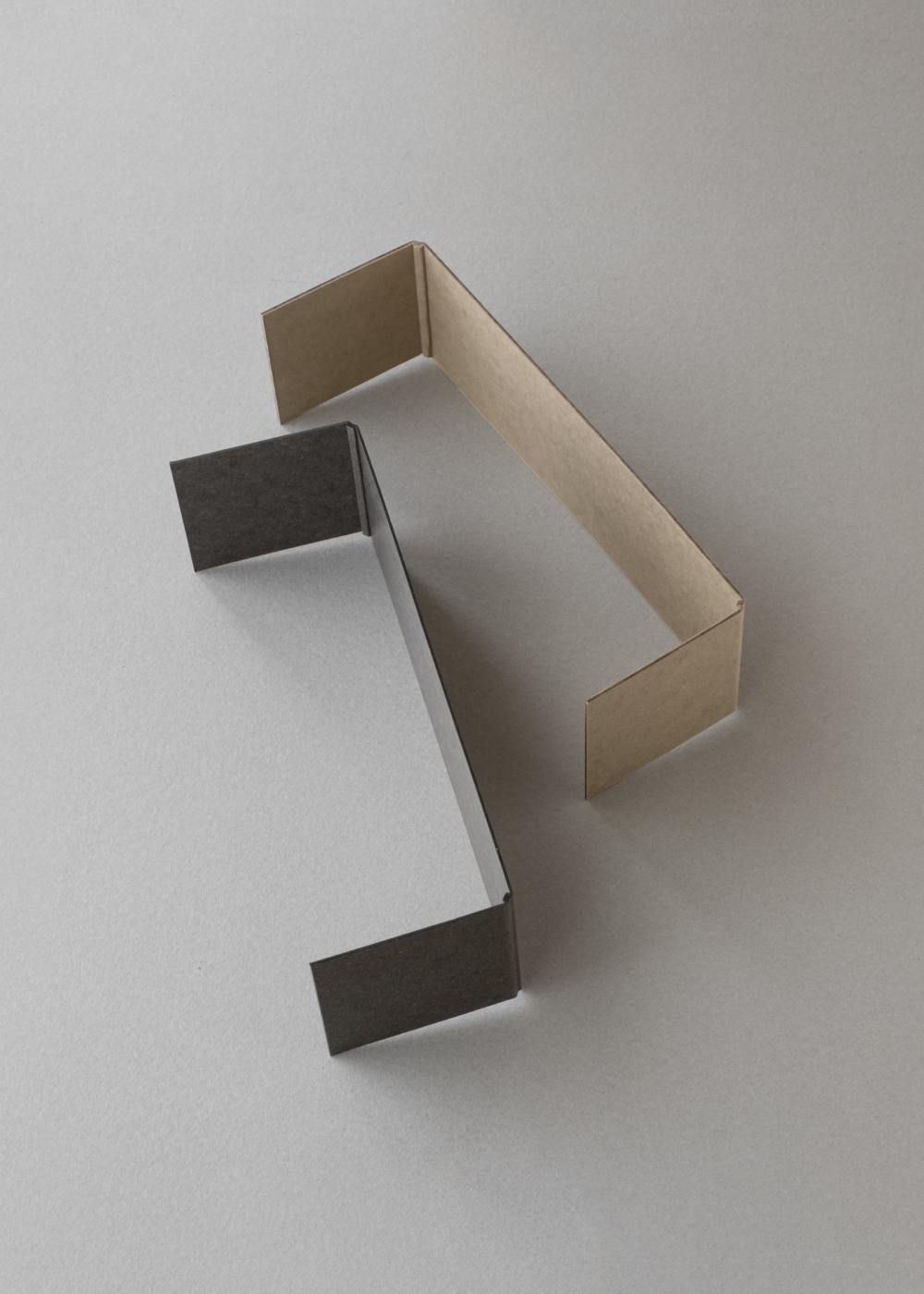

Box Divider

¥ 330 Including sales tax